Navigating the Challenges of Electric Powertrain Design

Understanding the Basics of Electric Powertrain Design

The transition to electric vehicles (EVs) is reshaping the automotive industry, with electric powertrains at the heart of this transformation. An electric powertrain converts energy into motion, involving components like the battery, inverter, and electric motor. While the concept may sound straightforward, designing an efficient and reliable electric powertrain presents several challenges.

One of the primary challenges is achieving the right balance between performance and efficiency. Engineers must ensure that the powertrain delivers sufficient power for acceleration and speed while maximizing energy conservation. This balance is crucial to enhance the vehicle’s range and overall performance.

Battery Technology and Its Impact

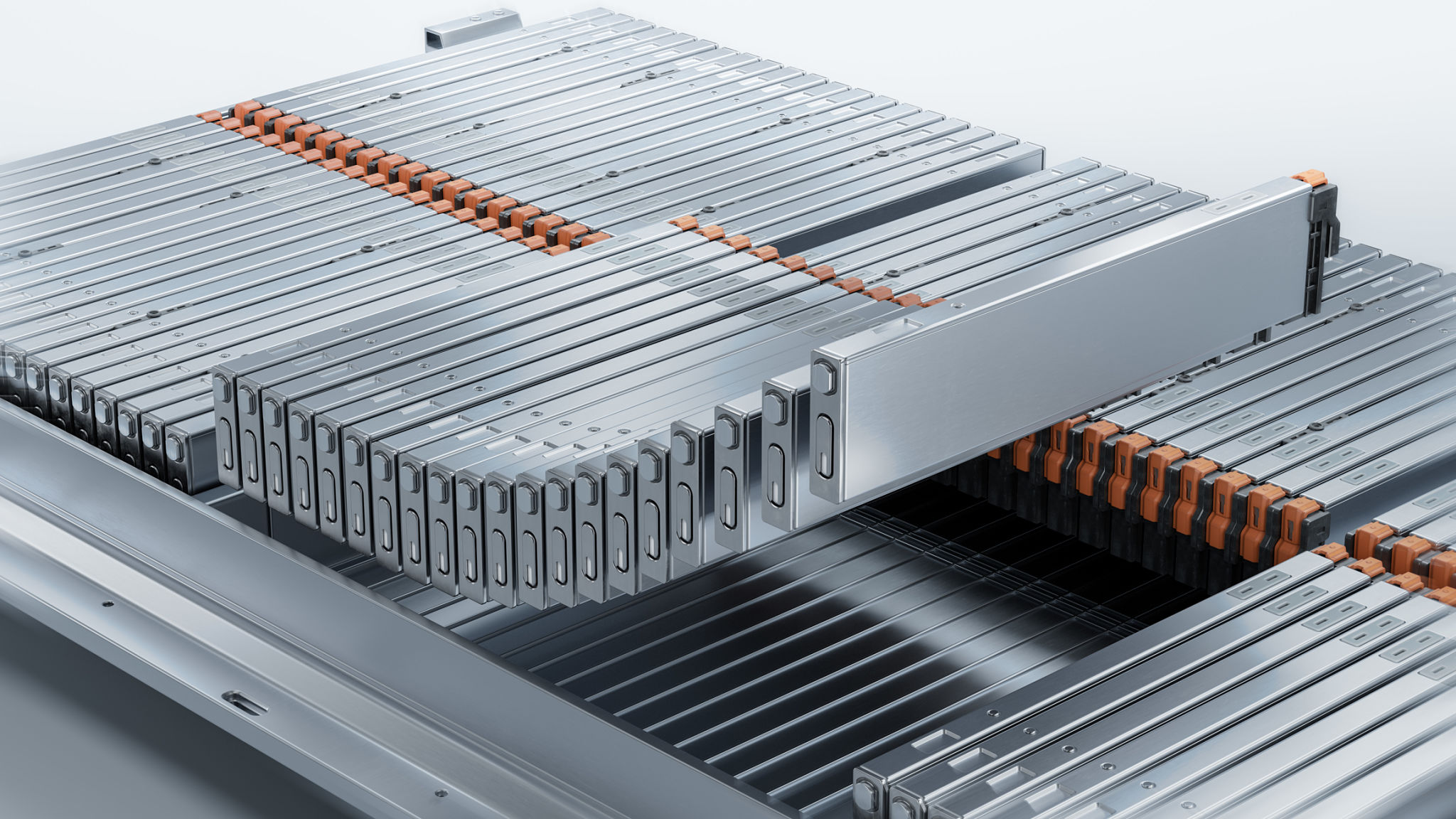

Batteries are the lifeblood of electric vehicles, and their design significantly influences the powertrain's performance. The challenge lies in developing batteries that provide high energy density while being lightweight and cost-effective. Moreover, battery technology must evolve to offer faster charging times without compromising safety.

The choice between different battery chemistries, such as lithium-ion and solid-state batteries, also plays a crucial role. Each type has its advantages and limitations, affecting factors like energy capacity, longevity, and thermal management.

Thermal Management Systems

Effective thermal management is essential to ensure the longevity and safety of electric powertrains. Excessive heat generated by batteries and motors can lead to degradation and potential failure. Therefore, designing advanced cooling systems that efficiently dissipate heat is paramount.

- Liquid cooling systems

- Air cooling mechanisms

- Phase change materials

Inverter and Motor Design Considerations

The inverter and motor are integral components that convert DC power from the battery into AC power needed to drive the electric motor. The challenge lies in ensuring these components are compact, efficient, and capable of delivering high performance under varying driving conditions.

Advancements in semiconductor materials, such as silicon carbide, offer promising improvements in efficiency and power density. These innovations play a vital role in overcoming current limitations in inverter design.

Regenerative Braking Systems

Regenerative braking systems are a key feature of electric powertrains, allowing energy to be recovered and fed back into the battery during deceleration. Designing such systems requires meticulous attention to detail to optimize energy recovery without compromising braking performance.

This involves fine-tuning the control algorithms that manage the transition between regenerative braking and conventional friction braking to ensure a seamless driving experience.

The Role of Software in Powertrain Optimization

Software plays an increasingly important role in optimizing electric powertrain performance. Advanced algorithms manage everything from energy distribution to predictive maintenance, enhancing both efficiency and reliability. Software updates can also provide improvements post-production, extending vehicle lifespan.

Moreover, software integration facilitates real-time monitoring of powertrain components, allowing for proactive adjustments and diagnostics that can prevent potential issues before they arise.

The Future of Electric Powertrain Design

As technology advances, electric powertrain design will continue to evolve, driven by innovations in materials science, electronics, and software development. The future holds exciting possibilities for enhancing performance, range, and sustainability.

By addressing current challenges and leveraging emerging technologies, engineers are paving the way for more efficient, reliable, and environmentally friendly electric vehicles that will redefine our approach to transportation.