The Benefits of E-Axle Optimization in Electric Vehicles: Boosting Performance and Efficiency

Understanding E-Axle Optimization

Electric vehicles (EVs) are revolutionizing the automotive industry, offering a cleaner, more efficient alternative to traditional gasoline-powered cars. A key component driving this innovation is the e-axle, an integrated system combining electric motors, power electronics, and transmissions. Optimizing this component can significantly enhance vehicle performance and efficiency.

An optimized e-axle can lead to smoother acceleration, improved energy efficiency, and a more refined driving experience. By refining the e-axle design, manufacturers can reduce the overall weight of the vehicle, leading to enhanced efficiency and extended range.

Boosting Vehicle Performance

One of the primary benefits of e-axle optimization is the boost in vehicle performance. Enhanced e-axle systems can deliver higher torque output, providing quicker acceleration and improved climbing capabilities. This is particularly beneficial for larger vehicles like SUVs and trucks, which require more power to operate efficiently.

Moreover, optimized e-axles can improve vehicle handling and stability. By precisely controlling the power distribution to each wheel, these systems enable better traction and maneuverability, enhancing the overall driving experience.

Enhancing Energy Efficiency

Energy efficiency is a critical factor in the design and operation of electric vehicles. An optimized e-axle system can significantly reduce energy consumption, extending the range of the vehicle on a single charge. This is achieved by minimizing energy losses during power conversion and transmission.

Additionally, optimized e-axles can contribute to regenerative braking systems, allowing the vehicle to recover energy that would otherwise be lost during braking. This recovered energy can be stored in the battery, further enhancing efficiency and range.

Reducing Manufacturing Costs

Another advantage of e-axle optimization is the potential to reduce manufacturing costs. By integrating multiple components into a single system, manufacturers can simplify the assembly process and reduce the number of parts required. This can lead to lower production costs and, ultimately, more affordable electric vehicles for consumers.

- Streamlined component integration

- Reduced material costs

- Improved production efficiency

Environmental Impact

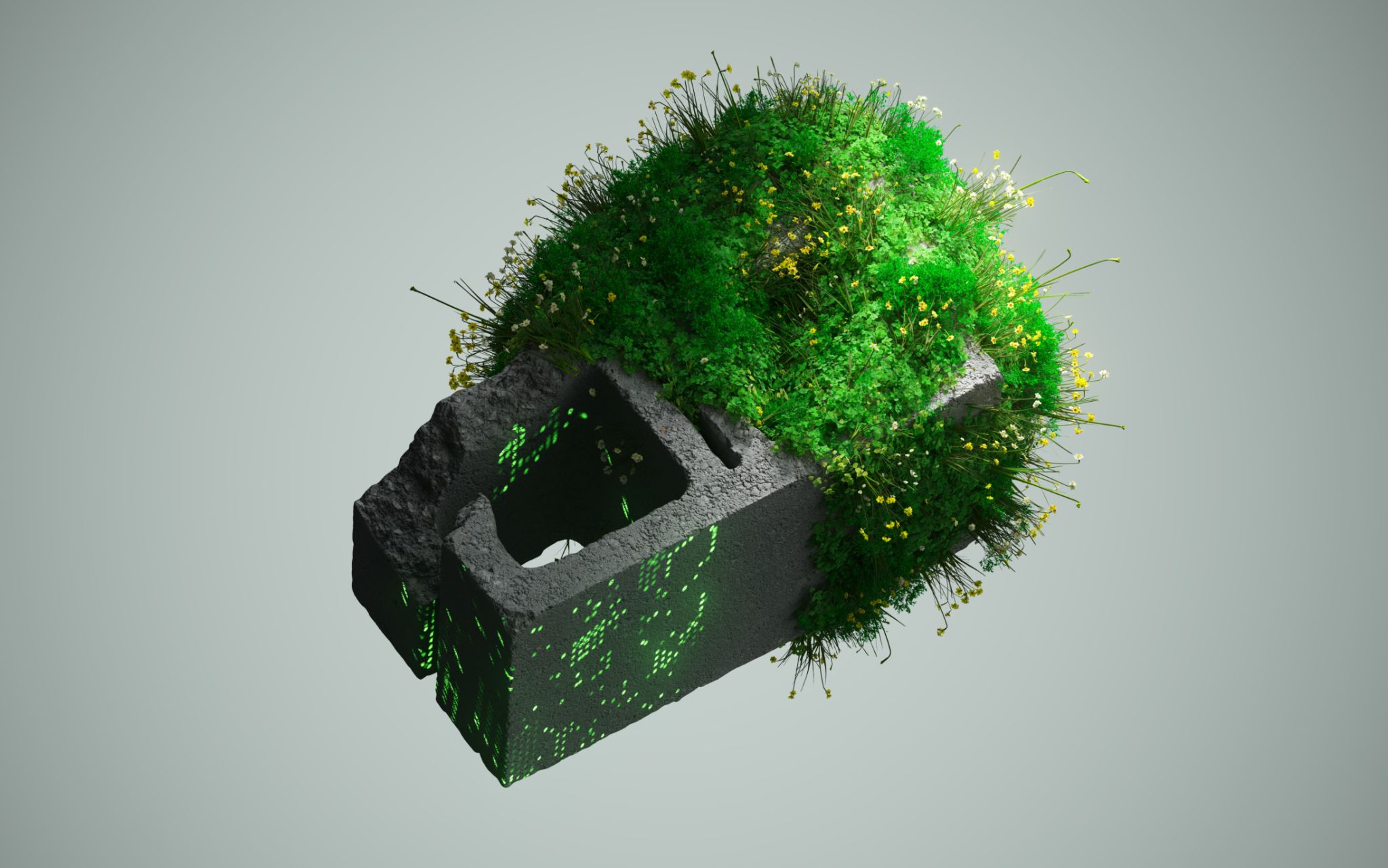

Optimized e-axles not only enhance vehicle performance and efficiency but also contribute to a reduced environmental impact. By improving energy efficiency and enabling longer ranges, these systems help lower the carbon footprint of electric vehicles, making them an even more sustainable choice.

Furthermore, the reduction in manufacturing costs and materials also aids in minimizing the environmental impact associated with production. This holistic approach to sustainability is vital in the transition to a greener automotive industry.

The Future of E-Axle Technology

As technology continues to advance, the potential for further e-axle optimization grows. Future developments may include more compact designs, increased power output, and even greater energy efficiency. The ongoing research and innovation in this field promise to propel electric vehicles to new heights, making them more accessible and practical for consumers worldwide.

In conclusion, e-axle optimization is a critical factor in the evolution of electric vehicles. By enhancing performance, efficiency, and sustainability, this technology is paving the way for a cleaner, more efficient future in transportation.